High precision tools are required for electronic jobs by professionals and hobbyists alike, and a soldering iron for electronics is high on the list. How does it differ from other, similar devices? What should you pay attention to when choosing a soldering iron for electronics? Which accessories should you choose to ensure both safe and comfortable work conditions?

High precision tools are required for electronic jobs by professionals and hobbyists alike, and a soldering iron for electronics is high on the list. How does it differ from other, similar devices? What should you pay attention to when choosing a soldering iron for electronics? Which accessories should you choose to ensure both safe and comfortable work conditions?

- Soldering irons for electronics – specifications

- Types of soldering irons for electronics

- Soldering irons for electronics and necessary accessories

- Soldering irons for soldering electronics

- Which electronics soldering iron is best for an electrical company?

- Which soldering iron is best for electronics – summary

Soldering irons for electronics – specifications

Soldering irons are used for many metal bonding needs, including for joining pieces of sheet metal, joining wires and various repairs. They are also essential in electronics, where work requires a high level of precision.

When working on a computer motherboard, for example, you cannot afford to damage delicate parts. In addition, an electronic soldering iron should be equipped with power and temperature control functions. Also pay attention to the antistatic properties.

Types of soldering irons for electronics

Three types of soldering irons usually have the above characteristics:

- heater (resistance) soldering irons,

- soldering stations,

- hot air soldering irons.

The heater soldering iron is the simplest. It has a heater that generates heat and then conducts it to the tip via a wire. It is very light and handy to use, and is easily connected to the power supply. What’s more, changing the tip is very easy.

Heater soldering irons are considered to be the most universal type, and are used for many different jobs in electronics. They are also recommended for beginners mastering this type of soldering. The price is another advantage, with the cheapest heater models available for under ten pounds.

Soldering stations, on the other hand, are more advanced tools. They are usually equipped with a soldering iron as one of the elements. A control panel is used to set the parameters and select additional functions, which in many models comes in the form of a digital display. Good soldering stations should offer the possibility to precisely adjust the temperature, e.g. in a range of 200-480°C, as well as keep it stable, and even remember the selected settings.

Hot air soldering irons can come as both separate tools and part of a soldering station. To heat the material, it uses air with a temperature in the range of e.g. 100-500°C. It requires more skill than a heater soldering iron, among other reasons because of its weight.

Hot air soldering irons can be used for many jobs . They work well with electronics, as they let you safely and conveniently solder and desolder surface mounted devices (SMD). In addition, they can be used for warming, defrosting, drying paint, removing adhesives and shrinking heat-sealed foil.

-

Soldering Station – digital – with soldering iron and holder – 90 W – LCD 79.00 GBP

-

Soldering Station – digital – with soldering iron and holder – 80 W – LCD

-

Set Soldering Station with Pre-Heating plate and 2 Clamps + Accessoires 199.00 GBP

-

Set Soldering Station with Tin Roller Clamp and Soldering Smoke Vent + Accessoires

219.00 GBP179.00 GBP

Soldering irons for electronics and necessary accessories

Regardless of how you use a soldering station , you should consider some universal accessories. These could be:

- tips for soldering irons,

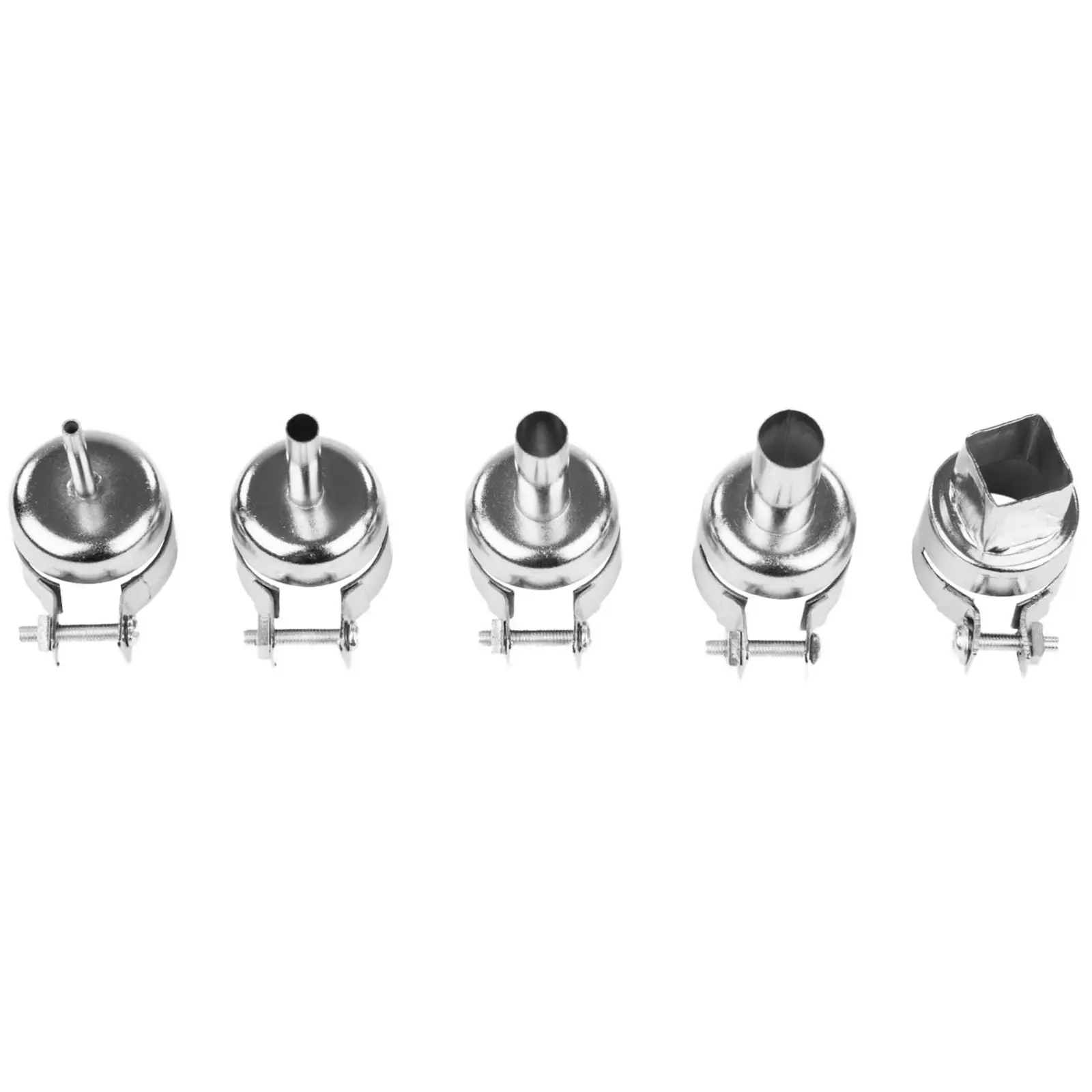

- hot air nozzles,

- tip cleaning stands,

- IC-popper lifting devices,

- solder fume extractors,

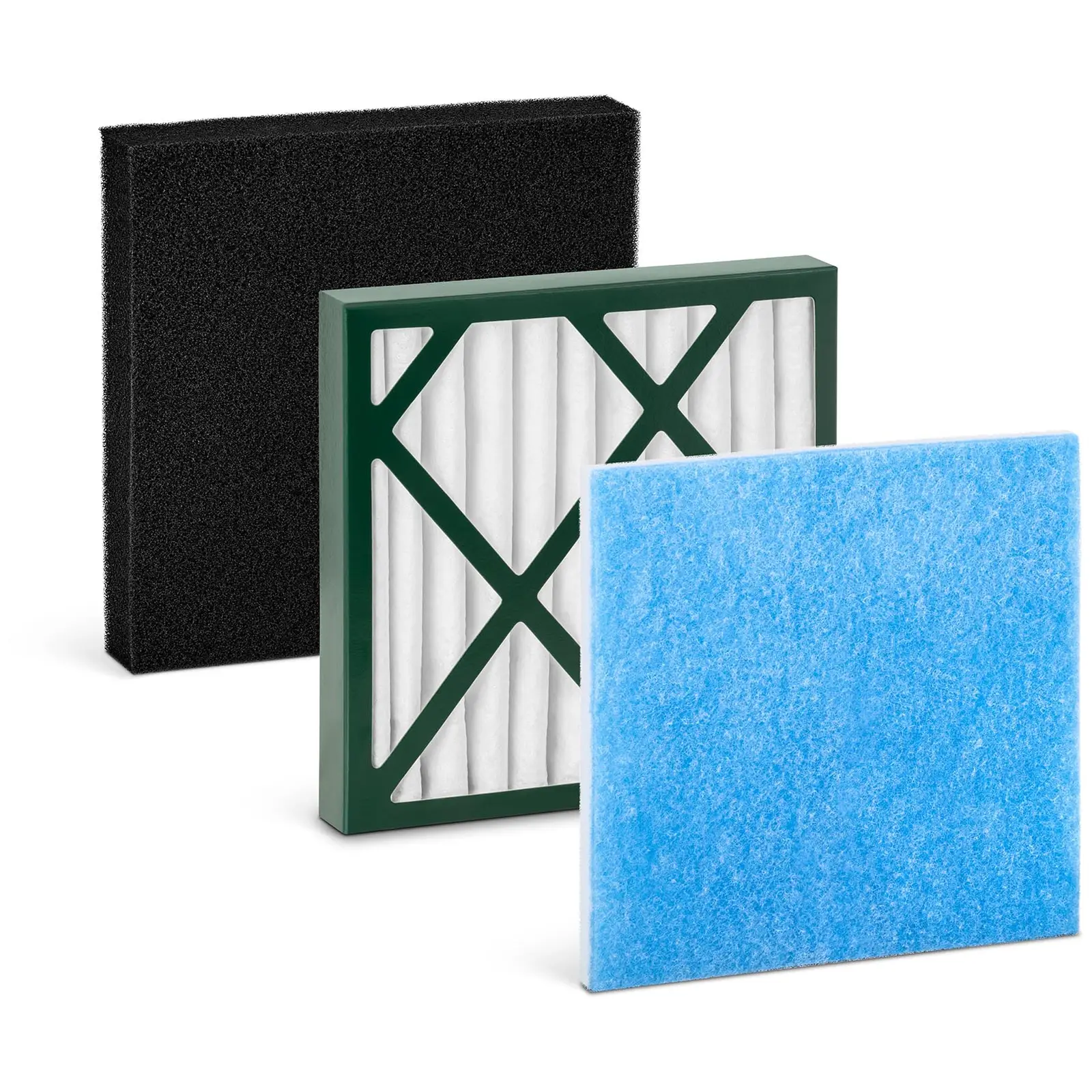

- absorber filters,

- lamps with a magnifying glass.

Tips for soldering irons are elements that must be replaced in the event of burnout. In order to clean them during work, you can use a special stand with a sponge or a metal cleaner. However, the use of nozzles of various shapes for hot air solders depends on the specific task. A practical accessory is an IC-popper – making it much easier to pick up hot components.

Fume extractors, on the other hand, increase work safety and comfort. Models with a compact, ergonomic design can come in handy even in small hobby workshops, as they ensure the removal of harmful fumes. In order for them to effectively do their job, you need to replace the filters from time to time.

The second, more professional type of absorbers are devices designed for two workstations at the same time. They are primarily used in electronic repair shops and industrial plants.

Soldering irons for soldering electronics

What exactly is a soldering iron used for in electronics? In electronics, soldering irons are primarily used for repairing various components in devices such as computers, printers, water conditioners, autoclaves and many others. They are suitable for soldering and desoldering BGA, SOIC, CHIP, QFP, PLCC, SMD and IC components.

If you deal with PCB repairs, a hot air soldering iron with a small nozzle may be the best solution for maximum precision. In this case, delicate components like printed circuits will not come into contact with the binder.

-

Set Soldering Station with Tin Roller Clamp and Soldering Smoke Vent + Accessoires

219.00 GBP179.00 GBP -

Set Soldering Station with Pre-Heating plate and 2 Clamps + Accessoires 199.00 GBP

-

Soldering Station – with hot air gun – 550 W – LED display

-

Soldering Station – 2 Displays – 730 Watt – Basic 95.00 GBP

Which electronics soldering iron is best for an electrical company?

For a professional electrician, one device will probably not be enough. For this reason, it is necessary to consider which types of soldering iron an electrician will really need. There are several types to choose from, and the choice is not always obvious.

Soldering stations are recommended as the most versatile and precise option. We mentioned their advantages and possible applications earlier on in this article. They let you carefully adjust the parameters for a specific job, which means that with the appropriate accessories they can cope with virtually any task. The price is usually an indication of how professional a particular device is, and models for professional use will cost hundreds of pounds.

On the other hand, electricians also perform work that requires less precision, such as cable splicing. Transformer soldering irons are well suited for this purpose. Their wire tip heats up very quickly, so they are ready for use after a few seconds. They lie comfortably in your hand, although they are not very light, and many professional users cannot imagine working without them on certain jobs.

Which soldering iron is best for electronics – summary

A soldering iron for electronics is an irreplaceable tool not only in an electronic repair shop, but also for DIY use. It can be used to repair many different electronic components, as well as perform certain jobs in electronics. For high-precision jobs, heater (resistance) soldering irons, soldering stations and hot air soldering irons are usually used.

The simplest and cheapest option are heater models. They are generally appreciated for their universal scope of use. More advanced soldering stations, in turn, let you carefully adjust the parameters, making them perfect for professional precision work. The last type, using hot air, require a lot of skill, but allow you to work even on very delicate elements.

Which type you should choose depends on the type of repairs you carry out on a daily basis. When going for a particular model, you should always pay attention to the main parameters, but also to your needs. Choosing the right tools is crucial for every type of use: in a repair shop, for renovation works and in the construction industry.

Share