Porcelain tiles are an extremely elegant and durable material used on floors and walls in bathrooms, kitchens or on outdoor patios. You will often need to drill holes in them, e.g. for towel rails, pipes or electrical boxes. So how should you drill holes in porcelain tiles? Read our article and learn everything you need to know about drilling in porcelain tiles.

Porcelain tiles are an extremely elegant and durable material used on floors and walls in bathrooms, kitchens or on outdoor patios. You will often need to drill holes in them, e.g. for towel rails, pipes or electrical boxes. So how should you drill holes in porcelain tiles? Read our article and learn everything you need to know about drilling in porcelain tiles.

Drilling in porcelain tiles. Dry or wet?

Porcelain tiles are very tough, which is both an advantage and a disadvantage. They will last for many years to come, but drilling or cutting them can be nightmare for both DIY enthusiasts and professionals alike. Fortunately, when drilling you can choose the dry or wet method, depending on the type of material.

Dry drilling in porcelain tiles

Dry drilling tiles, including porcelain tiles, is usually done outdoors due to the large amount of dust generated during the process. Small shards may also appear. However, this method is considered to be cleaner than the wet method, and it does not require the use of additional accessories in the form of water tanks. All you need is a suitable drill bit and a drill, which we will discuss later on in this article.

The main disadvantage of dry drilling is that it is less accurate. The holes made often have jagged and rough edges, which is not suitable if they will later be visible. A good example is a hole for the drainage pipe of a sink or washing machine. Improper drilling can also make the drill bit wear out more quickly, resulting in the need to frequently replace it.

Wet drilling of porcelain tiles

For wet drilling, water is used to cool the tip of the drill bit. This not only extends the life of the drill, but also the accuracy of the drilling process, enabling the drilling of holes with smooth, burr-free edges.

A disadvantages of wet drilling in porcelain tiles is that it is generally more messy. During the process, water is splashed around the room, so the whole bathroom or kitchen will later need to be cleaned. You will also need to use an accessory to moisten the drill bit, although at home you can also use a wet sponge or cloth for this purpose. Professional renovation and construction companies, in turn, use special wet drilling machines. Do you want to set up a construction business? Read our next article on how to start a construction company.

Drilling in porcelain tiles. Which drill bits and tools should you choose?

Once you’ve chosen the right drilling method, it’s time to select the equipment to be used.

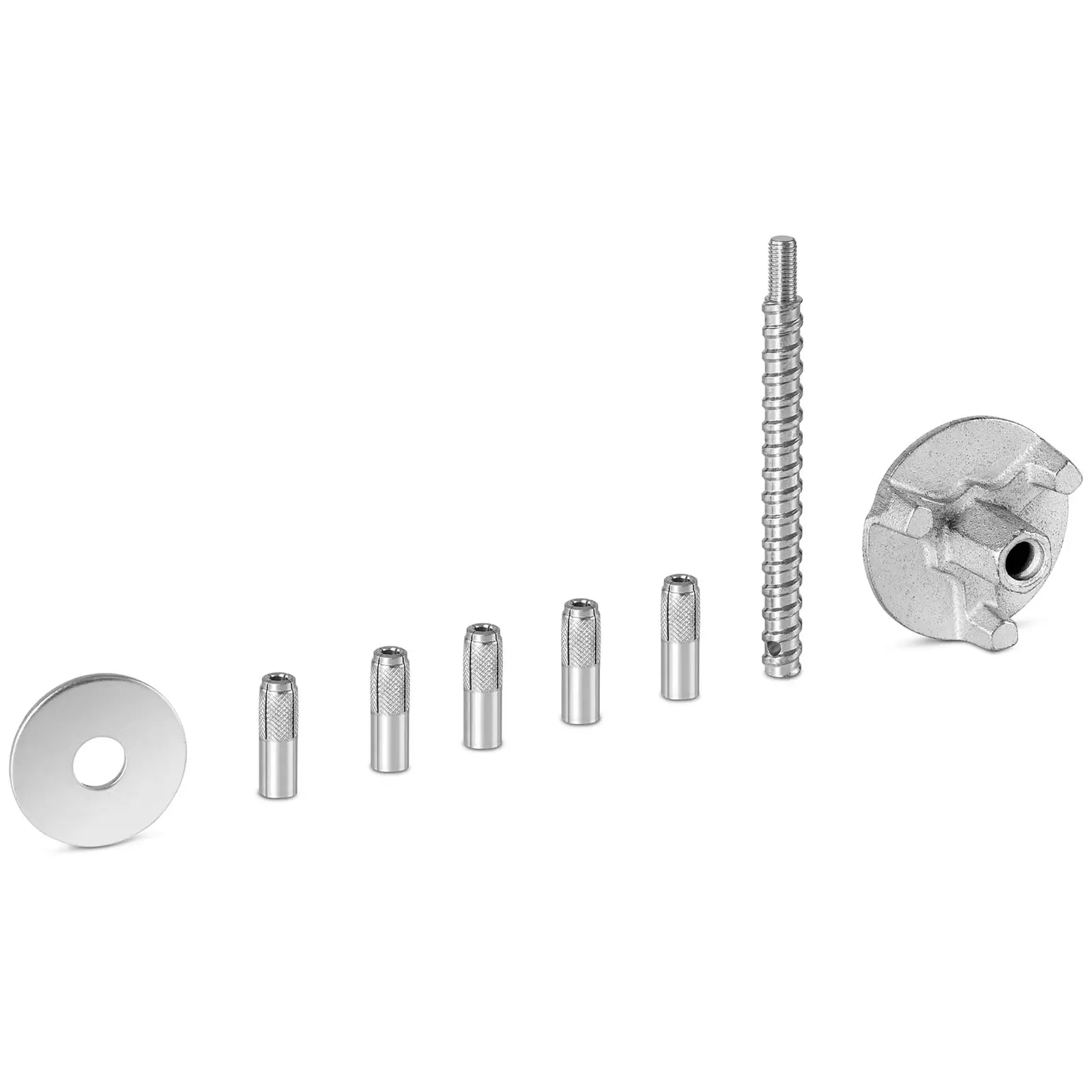

In the case of drill bits, the size of the hole you want to make and the hardness of the tiles are important. If you need to hang a towel holder or a basket for soap and shampoo bottles and simply need holes for screw anchors, then you will need a regular diamond drill bit. Make sure that its diameter corresponds to the size of the anchor. Holes for drainage, pipes, electrical boxes, etc. can be drilled with hole saws with diamond cutters.

Depending on how hard the tiles are, you will need to choose the right drill bit. The degree of hardness expressed using the Mohs scale is usually indicated on the packaging of the tiles. Diamond drill bits should be used for porcelain tiles and double-fired clinker tiles with a hardness of 9. In the case of tiles with a hardness of 6-8, diamond core hole saws can be used.

In addition to the drill bits, you also need a suitable drill. Impact drills are usually used in this case, but it is important that you remember to drill with the impact function off! Otherwise you will damage the tiles. You can turn on the impact only after you have drilled through the tile itself, and if the wall is made of brick. Find out which impact drill will work best.

What if the tiles are not installed on the wall yet? How can you drill a hole in porcelain tiles in this case? Here there are two options. The first are special drilling rigs, which are also used, for example, on concrete. They are used with diamond hole saws that are suitable for use on porcelain tiles. The second option is to use an angle grinder. With this option, special crown cutters are mounted on the grinder. You can also use a bench drill. If you are interested in such equipment, read our article about choosing the best bench drill for professional use.

How should you prepare for drilling in porcelain tiles?

Now that you know the basic techniques and have the necessary tools, you can start to drill holes in porcelain tiles.

Use a pencil or marker to mark where you want the holes to be. It is important that they are not close to the edges or corners of the tiles, in order to avoid the tiles cracking. If you intend to use dry drilling, attach dust catchers under the points you have marked, which will collect most of the dust and debris formed during drilling.

Once this is done, use a centre punch or a nail to make a small groove in the place of the hole, to prevent the drill bit from slipping. You can also use painter’s tape just to be sure, as its rough surface ensures stability while drilling. In addition, if you stick it on the tile crosswise, it will further reduce the risk of the tile breaking. In the case of larger holes, a good idea can be to drill a hole in the porcelain tile with a smaller drill bit first, and then gradually make it bigger with hole saws.

Your safety should be a priority at all times. When dry drilling, dust and debris can get into the eyes and nose, so special goggles and a protective mask are recommended.

How to drill in porcelain tiles – summary

After reading this article, you should know not only how to drill in porcelain tiles, but also what to use to do so. Drilling holes in the bathroom, kitchen or on your patio should no longer be an issue. However, remember to use the appropriate drilling method. Dry drilling is better outdoors, while wet drilling is recommended indoors. It is also important to choose the right drills bits and tools.

Are you looking for tips on what equipment you will need in a workshop? Read our articles about choosing the best equipment for DIY enthusiasts. Among other things, you will find out which drill driver will be the most suitable for specific jobs.

Share